Dock Serviceability

Zipline, Platform 2

DOCKING CONFIGURATIONS FOR AERIAL VEHICLES (P308479.US.01)

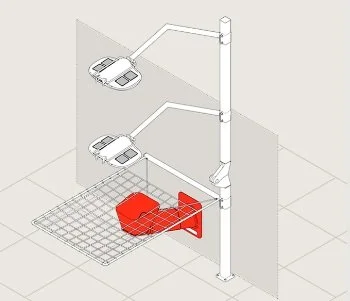

DOCK FOR AERIAL VEHICLES (P308477.US.01)

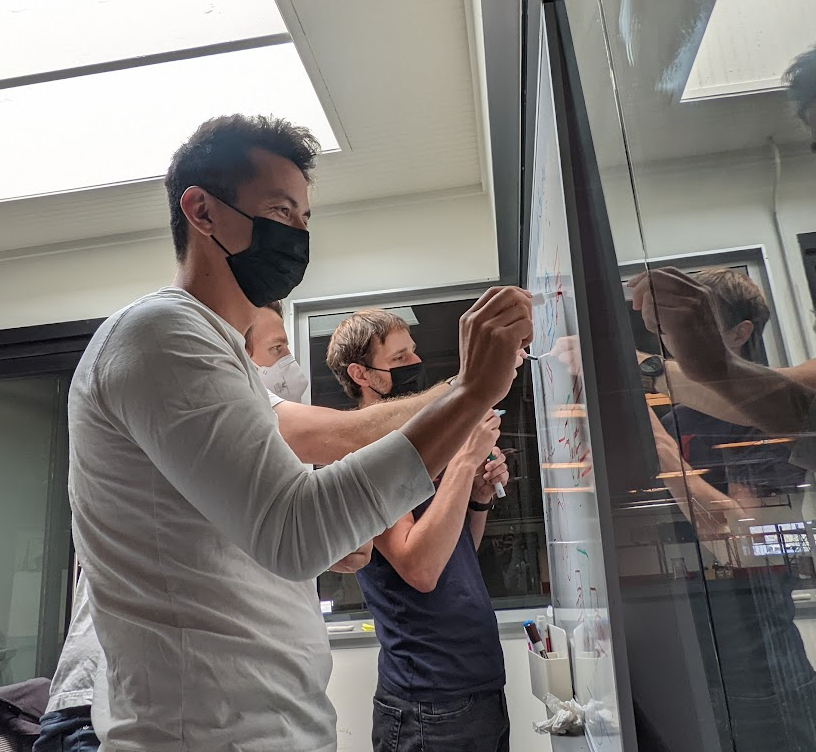

Delivery drones need a place to recharge, transfer data, load packages, and homebase for maintenance. While dock design was underway, everything between the ground (or wall, or roof) needed an architect. I drove Zipline’s P2 ground system architecture from blank page through early prototyping.

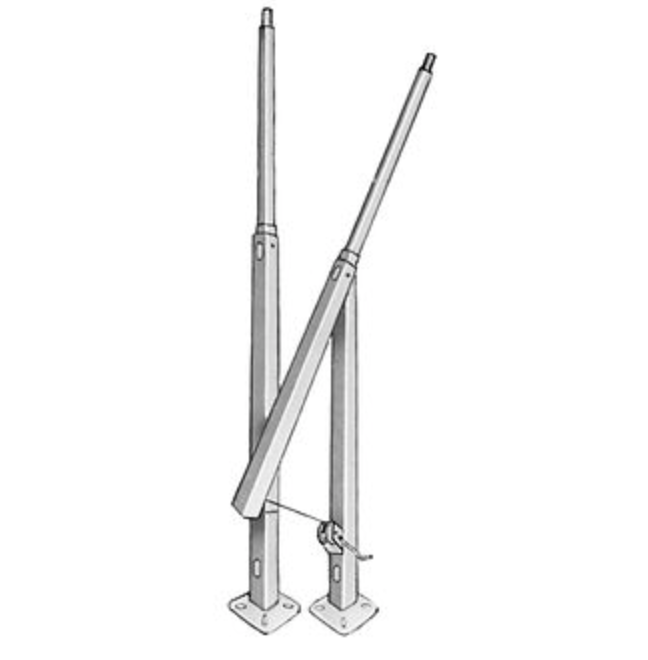

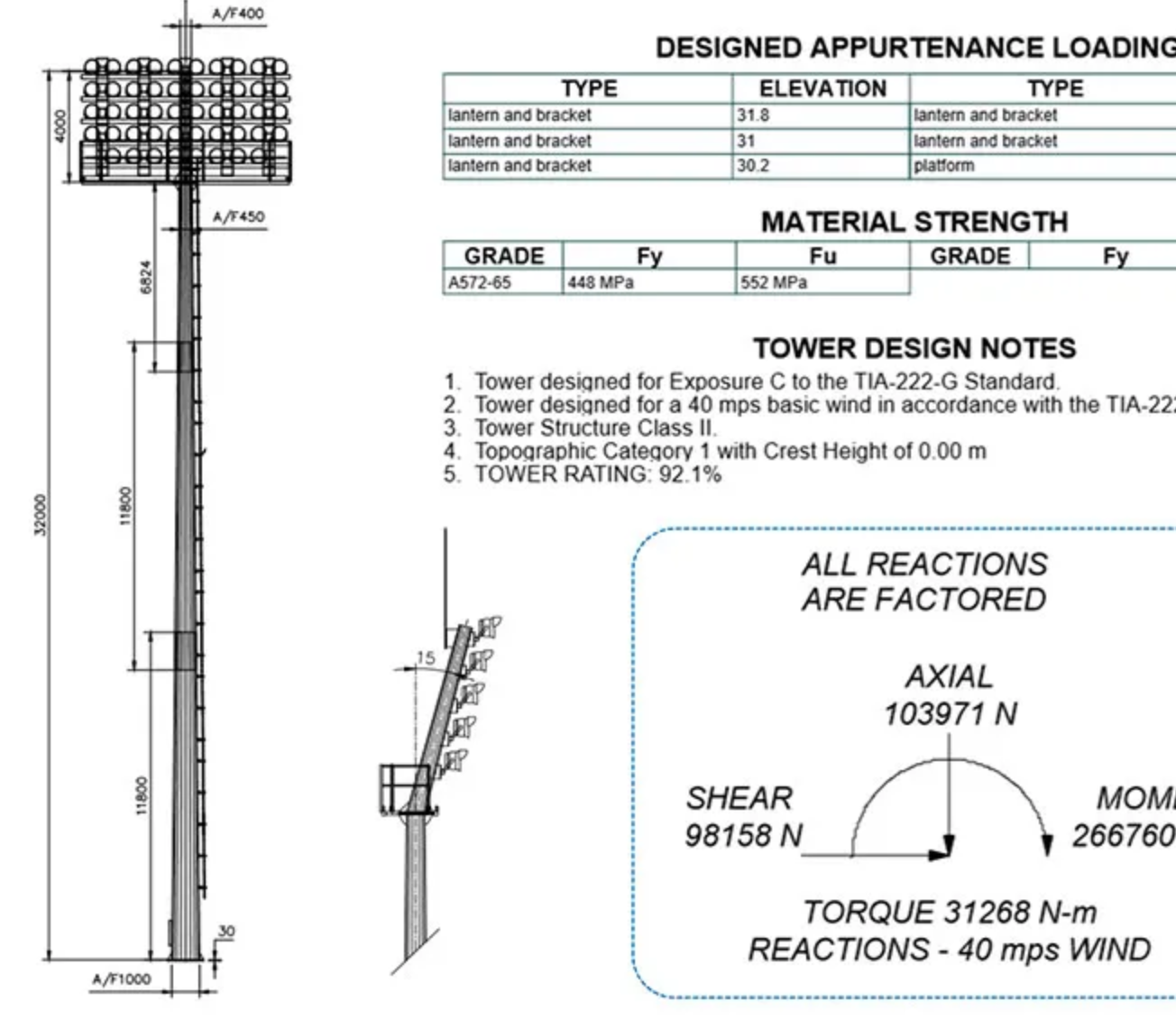

By prioritizing platform serviceability at scale across diverse markets, I landed on an actuated hinged tower to lift and lower our vehicles for service. This architecture also translated most cleanly to “try-it” modules for customers interested in trying Zipline’s logistics system without breaking ground.

Research, Tiger teams, Prototypes…

-

What is our ideal maintenance infrastructure? Who is on our ideal maintenance team? What is our ideal maintenance timescale? What are the easiest types of site retrofits for new construction? What markets should we focus on first?

-

What do other industries use for lift/lower systems? What are the strengths and limits of these systems? What extra requirements do these systems add? Do any of these systems win for international or developing markets? How do we transfer our hardware into a service vehicle?

-

Way too many big questions for one person to answer confidently. Group forum for requirements, ideation, and design. A feedback loop with platform leads. Prioritization of efforts in lieu of a team or lead.

-

What questions do we have and how can we answer them? Which option can we test fastest? How does this all look and feel? How do my ergonomics calculations actually feel? Does this feel safe?